APOGEE INSIGHT INTEGRATION OPTIONS

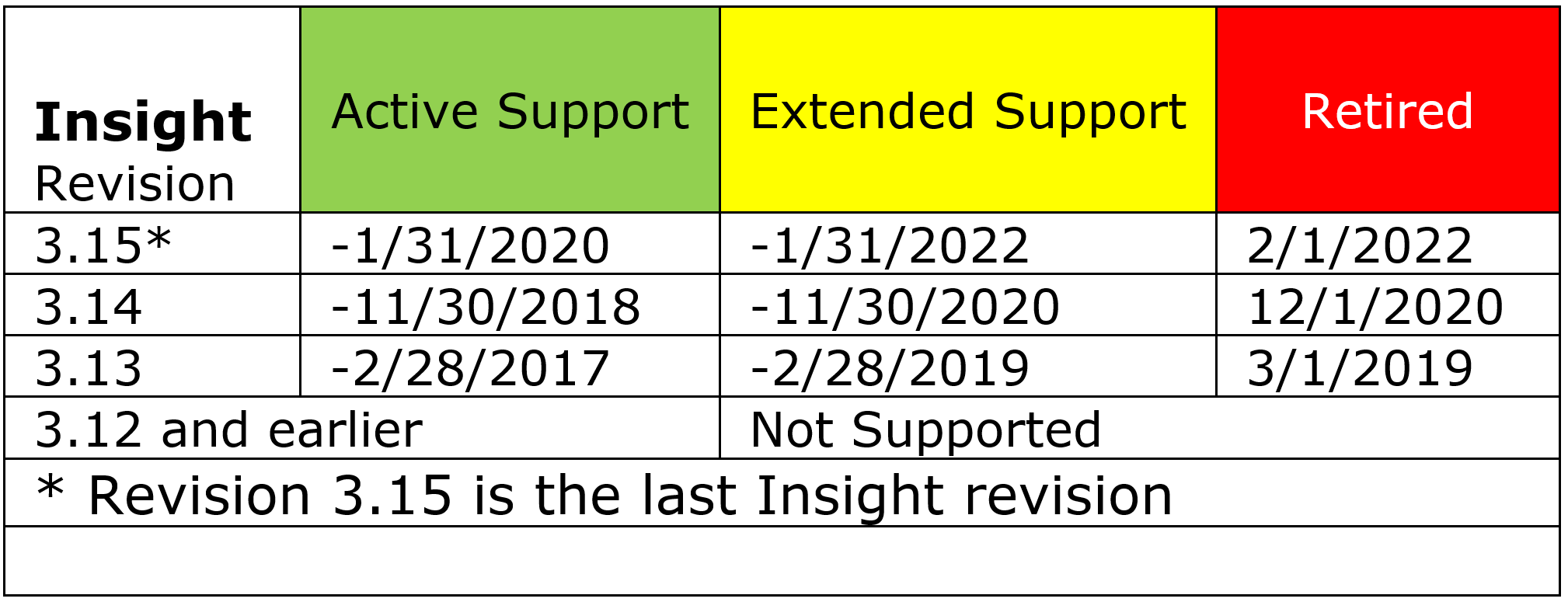

Insight Lifecycle

Siemens has announced the end of life date for the Apogee Insight system as Jan 2022 although new system sales were ended before Jan 2020. We have put this information together for you, to help you make the best decision possible when upgrading.

The Siemens upgrade path is to Desigo CC using their Apogee P2 driver. This upgrade is being offered at a discount to clients on Insight version 3.15. Earlier versions of Insight do not qualify for the discount. Only the latest version of the panel firmware is supported by the Apogee P2 driver.

For those looking for alternatives to the Desigo CC upgrade path there are a few options which retain at least some if not all of the apogee devices.

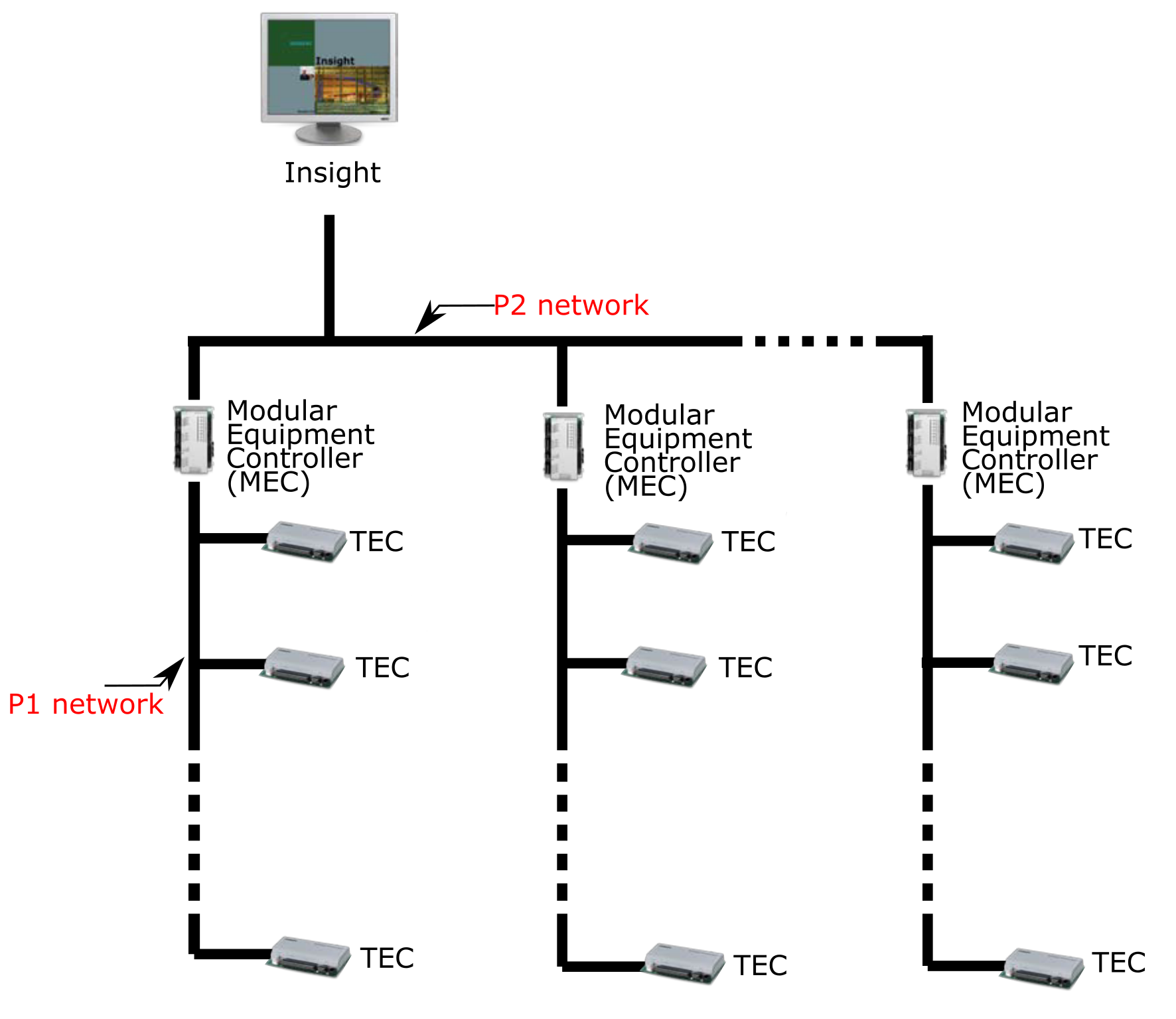

The Siemens Apogee system is a complex system which has evolved over the past 30 years. For an overview of the Apogee system architecture please refer to our page here.

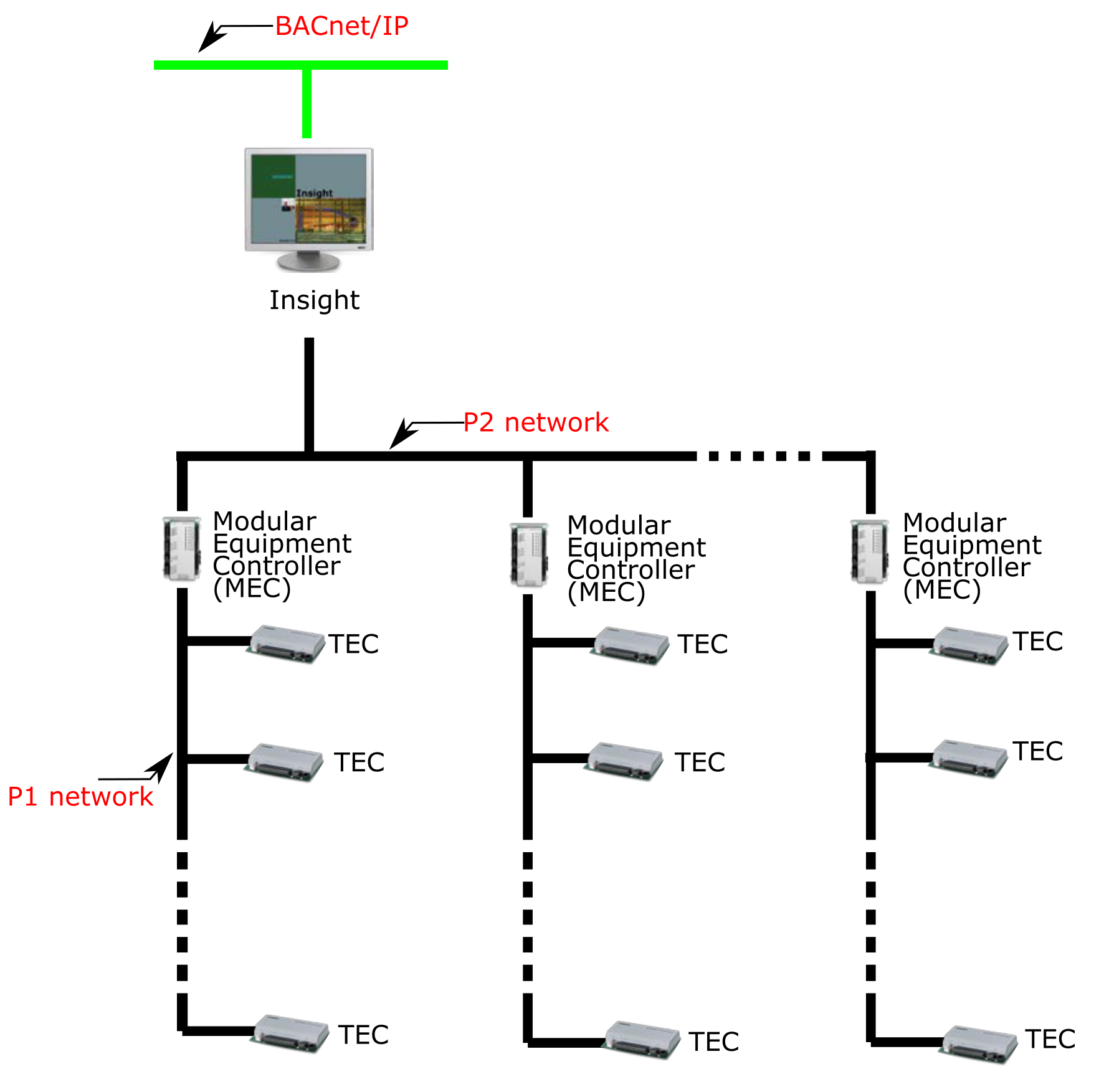

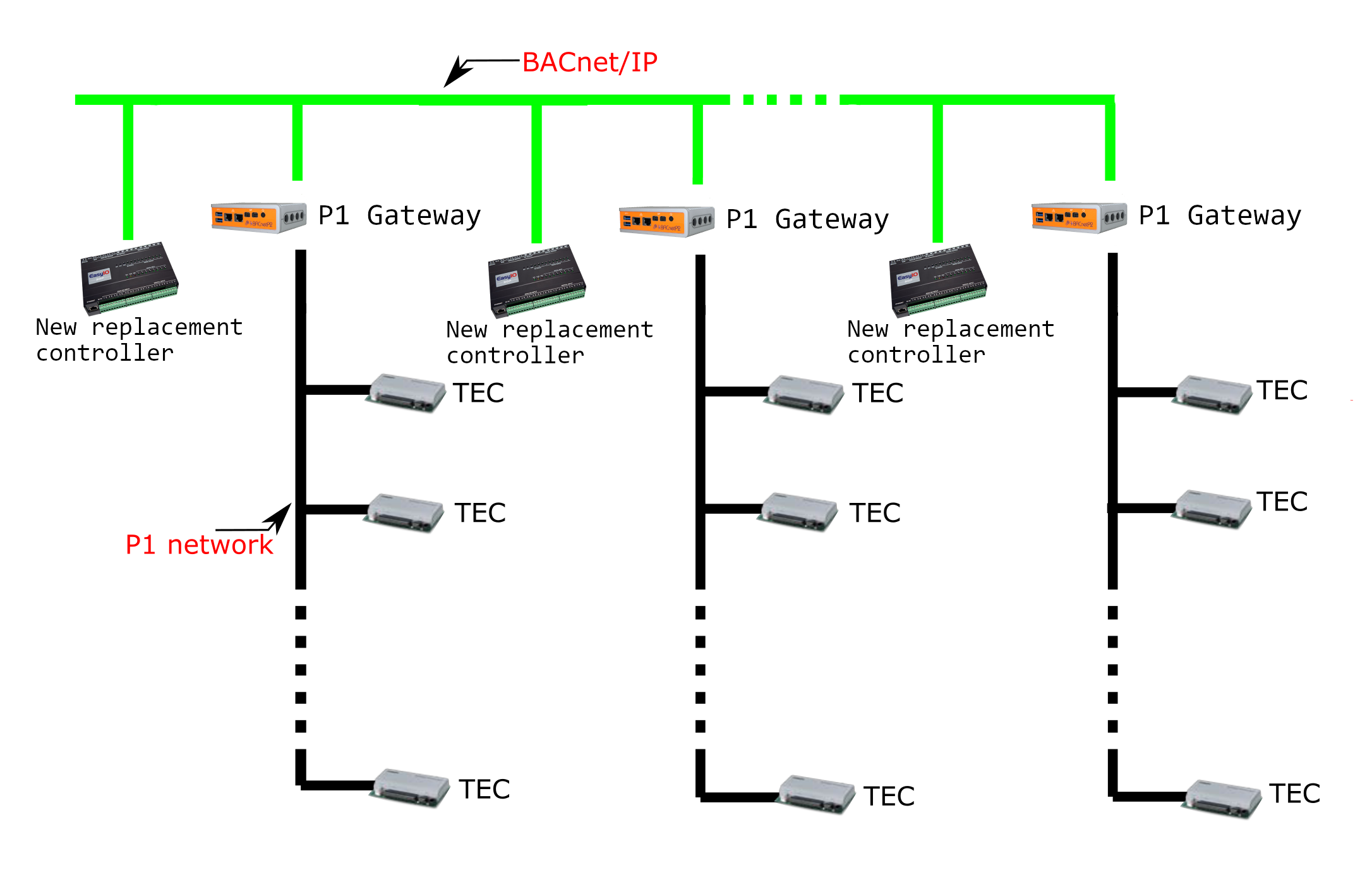

A simplified version of the Apogee system is shown below.

Some of the integration methods link into a specific physical layer of the Apogee architecture (P1 is a common choice) while others rely on integration options offered by Siemens themselves such as the BACnet server running on the Insight PC.

Each of these methods has its own advantages and disadvantages. Below we discuss the most common methods of integration.

P2 Integration Options |

|

1. Apogee BACnet Server |

|

| The Apogee BACnet server can be used to expose the Apogee panel / TEC points as BACnet read / write objects. Advantages: • Siemens supplied and supported solution. • Fast (low latency). Disadvantages: • Requires Siemens to engineer any changes. • Some versions of the BACnet server run on the Insight PC so Insight is required (must be retained). • Siemens has withdrawn this product so no longer available. |

|

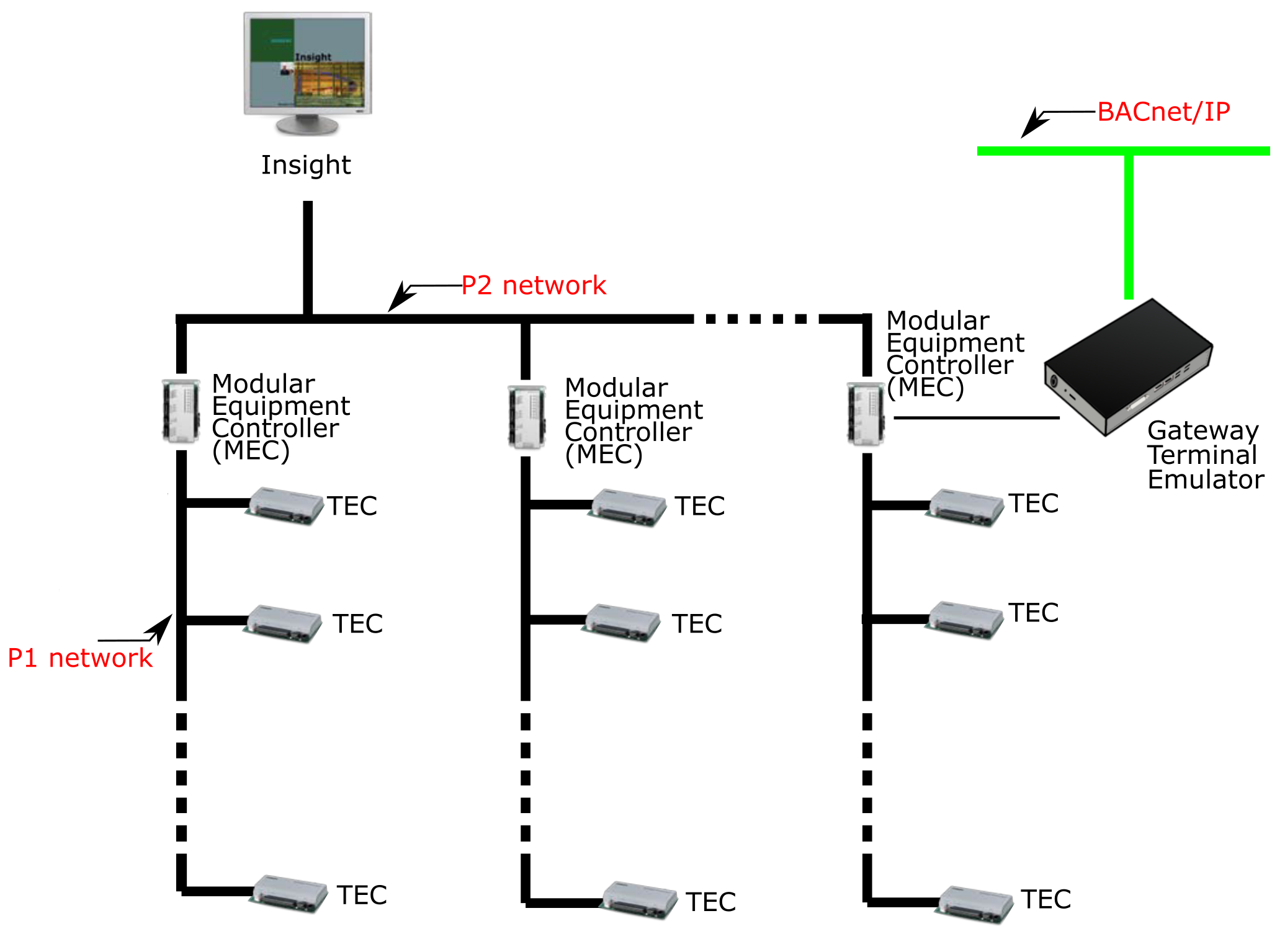

2. HMI to BACnet gateway (terminal emulation) |

|

|

This is the oldest and most common integration method. Each panel has a serial port connection which on legacy equipment is called the MMI but was renamed to HMI for political correctness one would assume. (MMI = Man Machine Interface) The HMI is a console like interface which is keystroke driven. This method of integration relies on a program to "type" commands to the HMI and poll for system point values and to command points to new values etc. The newer Siemens panels with Ethernet connections support the same console interface via telnet. Advantages: • Very simple (affordable) to write software interface. • Gives access to all panel and TEC points on the local BLN network. Disadvantages: • Very (very) slow on medium and larger systems. |

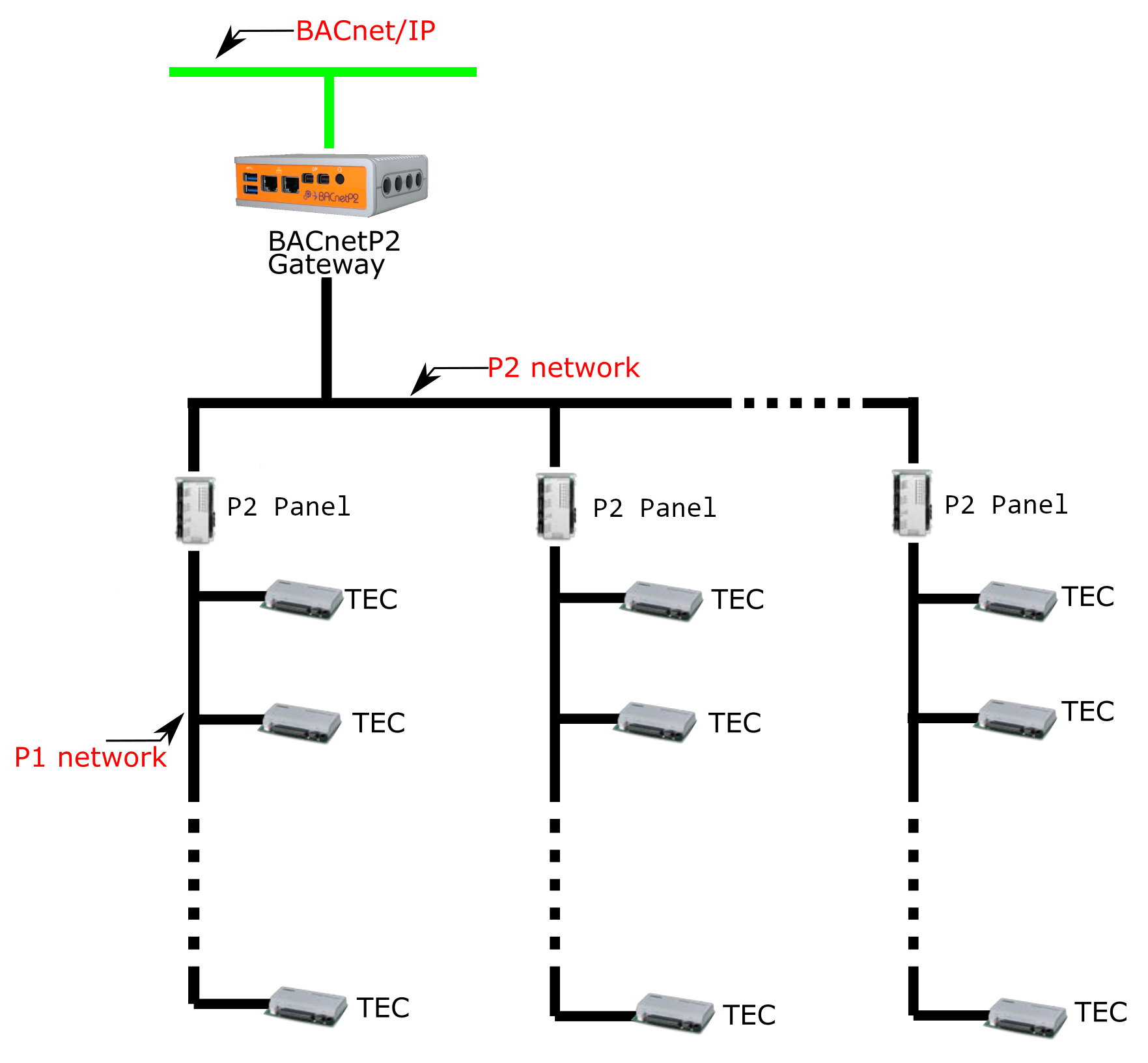

3. P2 to BACnet gateway |

|

|

The P2 protocol is a token passing (peer network) protocol. This means that a gateway can be added to the P2 BLN network without removing / replacing the panel as was the case with the P1 network. Advantages: • Fast (low latency) and with auto discovery, easy to engineer. Disadvantages: • Very difficult (expensive) to write software capable of P2 network communications. An example of a P2 to BACnet gateway, is our product: BACnetP2. BACnetP2 is a viable, affordable alternative to Desigo for upgrading Siemens Insight. To learn more about this please go to BACnetP2 and to learn what hardware you will need depending on which configuration you choose please see Methods of Integration with BACnetP2 |

|

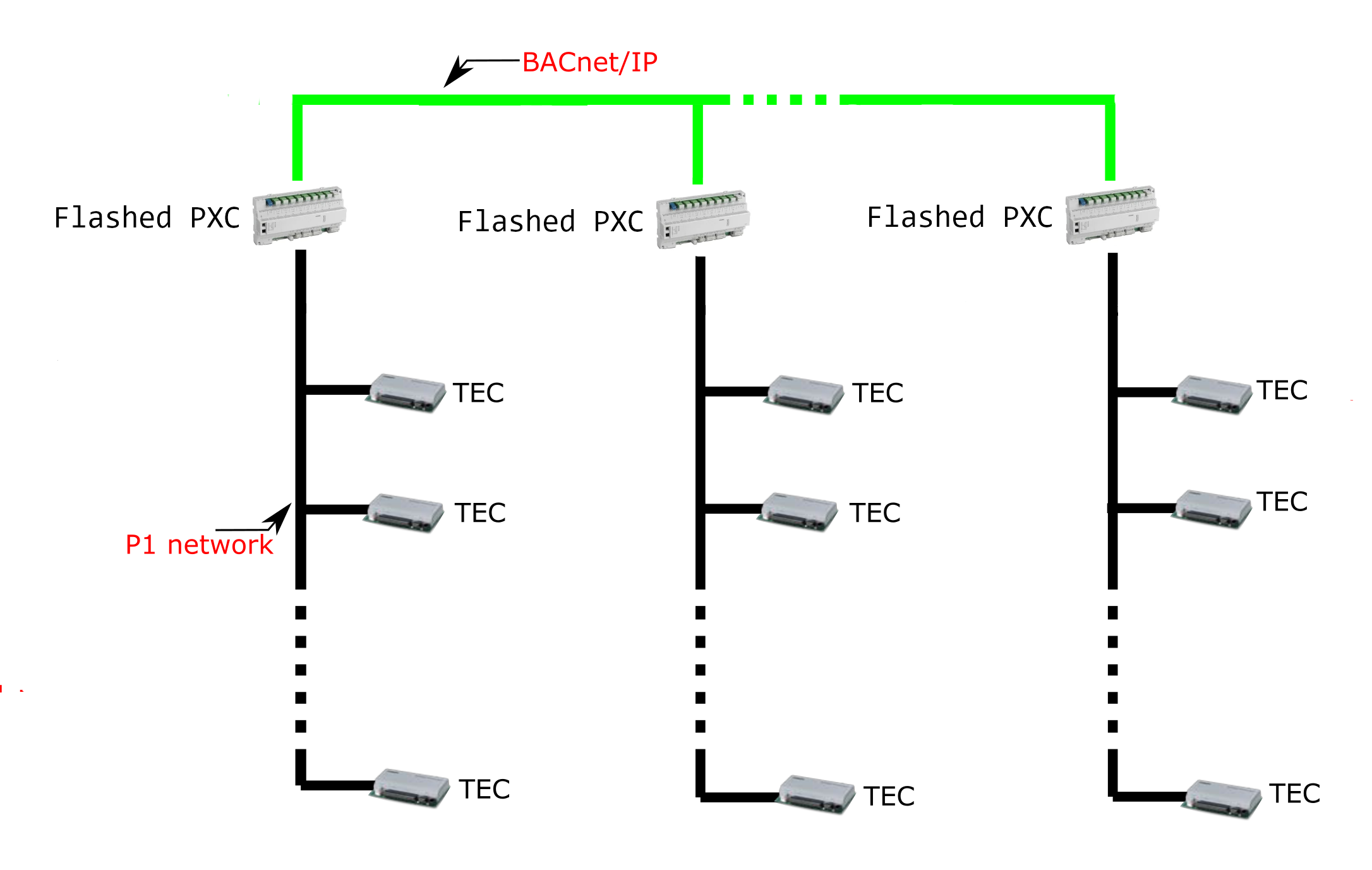

4. Flashing P2 PXCs to BACnet |

|

|

It is possible to flash the P2 PXCs to BACnet. What that means is that the firmware on each panel is "flashed" or upgraded to BACnet. This requires either in-house Apogee capability, a contractor with Apogee capability, or Siemens. Advantages: • Siemens supplied and supported solution. • Fast (low latency). Disadvantages: • Any attached P1 TEC devices lose their identity. TECs are not mapped as individual BACnet devices. • Requires Siemens to engineer any changes. • Can become expensive depending on the size of the site. We havee included a pricing comparison here: Pricing Comparison |

5. P1 to BACnet gateway |

|

| The P1 to BACnet gateway replaces each panel in the system and controls the P1 communications. The P1 protocol is a (M)aster (S)lave design and the gateway takes on the (M)aster role polling each connected TEC device in turn. This is the same design as BACnet MSTP. Advantages: • Fast (low latency) and with auto discovery, easy to engineer. Disadvantages: • None of the panel system data is integrated. • The TEC management code such as system AHU load scheduling will need to be created on the new system which adds costs and engineering time. • Any equipment such as AHUs that were attached to the panels will require new controller devices with suitable control function programming which adds costs and engineering time. |

|

Don't Miss OutStay updated about exciting new BACnetP2 features and developments. |